TVC-AI

TVC-AI | Redefining Investment Casting with Artificial Intelligence

In the investment casting industry, efficiency, precision and reproducibility are critical success factors. In response to these needs, and drawing on decades of industry expertise, TOPCAST is launching its flagship vacuum induction casting machine: the TVC-AI.Representing a true revolution rather than just an evolution, this machine introduces an AI-based operating mode for the first time, maximizing casting quality and simplifying operator interaction.

Combining proven TOPCAST vacuum casting technology with unprecedented computing power, the TVC-AI takes a completely new approach to defining cycle parameters, a process that has traditionally required time, experience, and costly trials.

AI mode: Excellence at the Touch of a Button

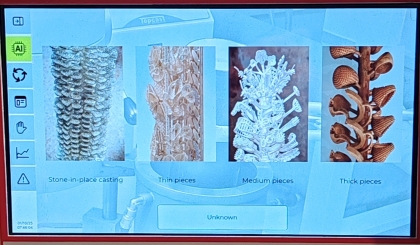

The TVC-AI's standout feature is its AI mode. This proprietary algorithm is the result of intensive machine learning, research and development, as well as the integration of a vast dataset based on TOPCAST's experience in precision casting. It completely eliminates the need for human intervention when defining operating parameters.In AI mode, the casting machine automatically determines the optimal operating sequence based on simple indications provided by the operator.

This mode enables all users to achieve optimal results with minimal effort, maximizing machine performance via a straightforward, intuitive interface.

The TVC-AI dynamically adapts to environmental and load conditions, ensuring that each casting is performed with calibrated parameters to achieve the best possible filling and surface quality for the cast parts. With the TVC-AI, TOPCAST offers an ecosystem of applied intelligence, not just a machine.

The introduction of AI mode marks a turning point, transforming one of the most delicate and complex manufacturing operations into a process that is accessible and reproducible, and which can be managed with pinpoint precision. The goal is clear: to free the operator from trial and error and allow them to focus on the quality and innovation of the final product. Vacuum casting has entered the era of artificial intelligence, and the TVC-AI is TOPCAST's ambassador for this new era.

Seamless ERP Integration for Highly Automated Cells

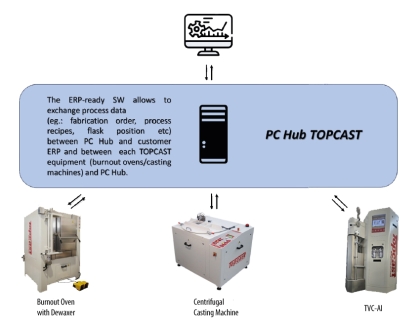

The TVC-AI is not only innovative in its approach to operator interaction; it is also a revolutionary leap in casting technology, engineered for unparalleled interactivity and automation at every stage of your production process.It's not just a casting machine; it's the backbone of a modern, smart factory.

- Seamless integration: TVC-AI is equipped with cutting-edge hardware and software for full connectivity and real-time monitoring via your existing ERP (Enterprise Resource Planning) system.

- Industry 5.0 Ready: This machine is fully compliant with Industry 5.0 standards and ensures intelligent interaction between advanced automation and human expertise.

Our ERP-ready Software Package and proprietary Flask Tag System allow you to follow and monitor the progress of the flask throughout the production chain and interact with the operator. For example, the correct burnout recipe can be automatically assigned to the burnout oven and the casting program related to the current flask can be automatically loaded.

The production progress status and all the process variables of the production cell are displayed in graphical and numerical form, batch by batch. This guarantees maximum quality and repeatability of the production cycle while simplifying the management and tasks of the production staff.

Technical data

| TVC-AI | ||||

| Crucible Volume | 280 cc | 380 cc | 500 cc | 700 cc |

| Crucible working capacity | 500 g Aluminum 1.5 kg Bronze 1.7 kg Silver 3.0 kg Gold |

650 g Aluminum 2.2 kg Bronze 2.4 kg Silver 4.5 kg Gold |

800g Aluminum 2.5 kg Bronze 3.0 kg Silver 5.5 kg Gold |

1.0 kg Aluminum 3.5 kg Bronze 4.4 kg Silver 8.0 kg Gold |

| Flask max. diameter (mm) | ||||

| Flask max. height (mm) | ||||

| Induction heating power | 15 kW | |||

| Vacuum pump | Internal | |||

| Pressure over vacuum | 3 bar | |||

| Max. temperature | ||||

| Granulation unit | ||||

| Industry 5.0 | ||||

| Automatic feeder for crucible replenishing | ||||

| Autotest with data report | ||||

| Monitoring system for data acquisition | ||||

| Flask and vacuum check before casting | ||||

| Flask temperature reading | ||||

| Flask cleaning before casting | ||||

| Vacuum leakage detector | ||||

| Oxygen Analyzer | ||||

| Main alloys | ||||

![]() Provided -

Provided - ![]() Available on request

Available on request