TVCs - Single Chamber

Pressure Over Vacuum Casting Machine

TVCs are fully automatic, robust, easy to use vacuum investment casting machines designed for small and medium sized laboratories. These machines operate on the well known concept of "pressure over vacuum", using both flanged and non-flanged (and therefore cheaper) perforated cylinders.Melting of the metal takes place in a protective atmosphere (nitrogen, argon or forming gas) and a powerful vacuum pump is supplied to obtain the maximum suction effect in the mould chamber.

The consumption of the graphite crucible is greatly reduced thanks to the gas washing process, which removes the oxygen within seconds of the charge being loaded.

The heating system consists of a medium frequency induction generator, while the temperature is measured by a thermocouple with an accuracy of 1%. It is also possible to effectively mix the alloy during casting by means of medium frequency pulses, which are automatically managed by the control system.

In addition, once the metal has entered the mould, compression is applied during solidification to reduce shrinkage porosity.

The control panel is simple and intuitive, with just three keys for normal management of the melting cycle, while a 7-segment LCD display shows temperature and power.

The machine runs an automatic cycle when the START button is pressed, and has eleven parameters for managing this cycle, so that the melting cycle can be customised according to the alloy used.

Technology & Features

Gas Wash Procedure

- Crucible loading operation introduces oxygen

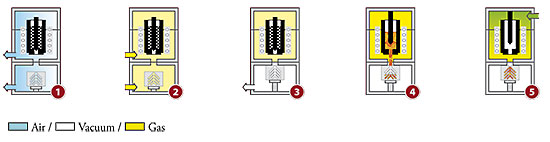

- The Gas Wash Purge procedure removes the oxygen (1) in a very fast and efficient way and then refills back the chambers with Argon or Helium gas (2)

- Compared with the traditional crucible protection with flow-meter regulation the consumption of gas is dramatically reduced and the alloys oxidation is minimized

- Moreover the crucible life is increased: TVC series crucible last up to 250 – 400 casting cycles according to the graphite quality

Melting

- Advanced Self Tuning thermoregulation (AST™) with exact temperature control of the melted alloys

- Medium frequency induction heating stirs the melted alloy and leads to a perfect homogeneity

- Pulse Stirring Management (PSM™) for an extremely low frequency stirring

Injection and Compression

- When the stopper opens, as soon as the molten metal fills the flask, a trigger is launched to the over pressure valve which will make the gas flow enter smoothly and quickly to compress the tree during the solidification phase to reduce shrinkage porosity

Tree protection after casting

- After the solidification phase, the flask cools down in a protective atmosphere to avoid oxidation.

- A blinking lamp will signal the operator that the cycle has ended and the flask can be removed

Technical data

| TVC3s | TVC4s | TVC10s | |

| Number of casting programs | 1 | 1 | 8 |

| Working Capacity of graphite crucible | 1 kg Au 0.5 kg Ag |

2 kg Au 1 kg Ag |

3 kg Au 1.5 kg Ag |

| Flask maximum diameter (mm) | Ø150 | Ø150 | Ø150 |

| Flask maximum height (mm) | 280 | 280 | 280 |

| Induction power | 3 kW | 4 kW | 8 kW |

| Vacuum pump | External | External | External |

| Pressure over vacuum | 2 bar | 2 bar | 2 bar |

| Max. temperature | 1250 °C | 1250 °C | 1250 °C |

| Shot maker | |||

| Autotest with data report | |||

| Touch screen instead of buttom control panel | |||

| Flask check before casting | |||

| Vacuum leakage detector | |||

| Oxygen Analyzer | |||

| Main alloys | Gold (Au), Silver (Ag), Copper (Cu), Bronze, Aluminium (Al) and their alloys | ||